Exactly How to Prevent Weld Undercut: Crucial Tips for Welders

Wiki Article

A Comprehensive Overview to Identifying, Averting, and Correcting Undercut Welding Issues in Your Welding Tasks

In the world of welding, coming across undercut problems is an usual challenge that can endanger the architectural integrity and general high quality of your welding projects. Keep tuned as we discover the crucial parts of determining, protecting against, and fixing undercut welding issues, offering you with beneficial understandings and techniques to boost your welding abilities to the next level.Usual Root Causes Of Undercut Welding

Undercut welding, an usual concern in welding processes, can be triggered by various variables that need to be meticulously identified and dealt with to guarantee the stability of the weld joint. One of the main causes of undercut welding is excessive heat input. When the welding specifications, such as voltage, existing, or take a trip speed, are not appropriately set, an extreme quantity of heat can be created. This excess warm results in the melting and succeeding elimination of the base product along the sides of the weld joint, creating a groove called undercut.One more typical cause of undercut welding is inappropriate welding strategy. Determining these root triggers and carrying out restorative measures is vital in protecting against and remedying undercut welding issues in welding jobs.

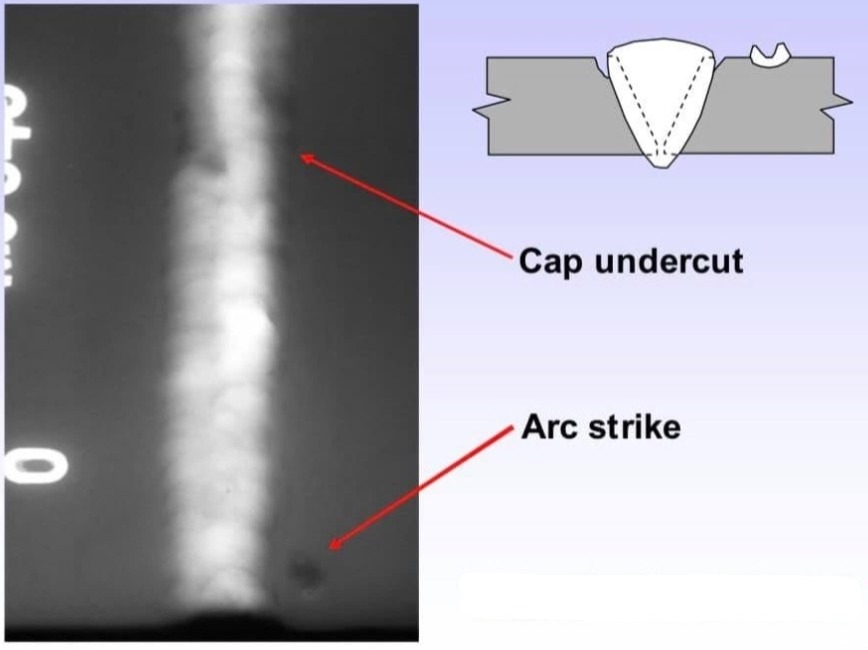

Identifying Undercut in Welds

To identify undercut accurately, appropriate lights and zoom devices are necessary to evaluate the weld joint thoroughly. Using devices such as a welding scale or a magnifying glass can aid in discovering also the tiniest undercut flaws. In addition, running a finger or a finger nail along the weld joint can often disclose undercut, as the surface area might feel unequal or have a dip where the undercut exists.

Preventive Steps for Undercut

Having a deep understanding of the reasons of undercut in welds enables for the application of efficient preventative procedures to keep weld top quality and integrity. These settings ought to be enhanced to protect against extreme heat input, which can lead to undercut development.

Techniques for Repairing Undercut

Boosting the welding present or reducing the travel rate can assist load in the undercut. Furthermore, transforming the welding strategy from a press to a drag or vice versa can likewise aid lessen undercut.

One more method is to make use of a weaving motion while welding to guarantee correct sidewall fusion and fill in the undercut. By oscillating the welding arc from side to side within the weld joint, the welder can deposit more filler material into the undercut areas, properly removing the issue.

In addition, grinding out the undercut and rewelding the joint can be a viable remedy for more serious undercut problems - Preventing weld undercut. This procedure entails eliminating the undercut section, preparing the base steel, and after that rewelding the joint with correct welding specifications and methods to stop undercut from returning

Specialist Tips for Staying Clear Of Undercut

Utilizing appropriate welding techniques and maintaining control over crucial welding specifications are crucial techniques for welders intending to avoid undercut in their weld you can try this out joints. One expert tip for avoiding undercut is to make certain proper joint preparation. This entails cleaning up the base steel thoroughly to remove any kind of contaminants that might bring about undercut formation. Additionally, selecting the ideal welding procedure and filler metal for the certain application can assist avoid undercut. Welders should also pay very close attention to the welding current and voltage setups, ensuring they are within the recommended variety to prevent getting too hot click here to find out more and prospective undercut. Keeping a constant traveling rate during the welding procedure is another necessary tip to stop undercut. By relocating at a steady pace, welders can make sure correct blend and minimize the chance of undercut formation. Lastly, examining the weld grain after completion can help identify any indicators of undercut at an early stage, permitting instant corrective action to be taken.Final Thought

In verdict, determining, avoiding, and taking care of undercut welding problems in your welding tasks is crucial for making certain strong and long lasting welds. Preventing weld undercut. By comprehending the common causes of undercut, having the ability to recognize it in welds, executing safety nets, and making use of appropriate strategies for taking care of undercut, you can avoid prospective concerns and create high-quality welds. Following professional suggestions for avoiding undercut can assist you improve your welding abilities and create much better outcomes in your jobsUndercut welding, a typical issue in welding procedures, can be triggered by various factors that require to be thoroughly identified and resolved to make sure the stability of the weld joint. Furthermore, running a finger or a finger nail along the weld joint can in some cases disclose undercut, as the surface area might really feel irregular or have a dip where the undercut exists.

Utilizing correct welding techniques and preserving control over vital welding criteria are vital methods for welders intending to protect against undercut in their weld joints.In final thought, recognizing, stopping, and taking care of undercut welding problems in your welding jobs is Extra resources important for ensuring strong and sturdy welds. By understanding the common reasons of undercut, being able to determine it in welds, applying preventive steps, and utilizing appropriate methods for repairing undercut, you can stay clear of potential concerns and produce premium welds.

Report this wiki page